A PHP Error was encountered

Severity: Notice

Message: Undefined variable: info

Filename: sales_center/saleslist.php

Line Number: 34

Baofu Konağı 3 # 105 NO.180 Meifeng RD Gulou Bölgesi Fuzhou Çin

A PHP Error was encountered

Severity: Notice

Message: Undefined variable: info

Filename: sales_center/saleslist.php

Line Number: 34

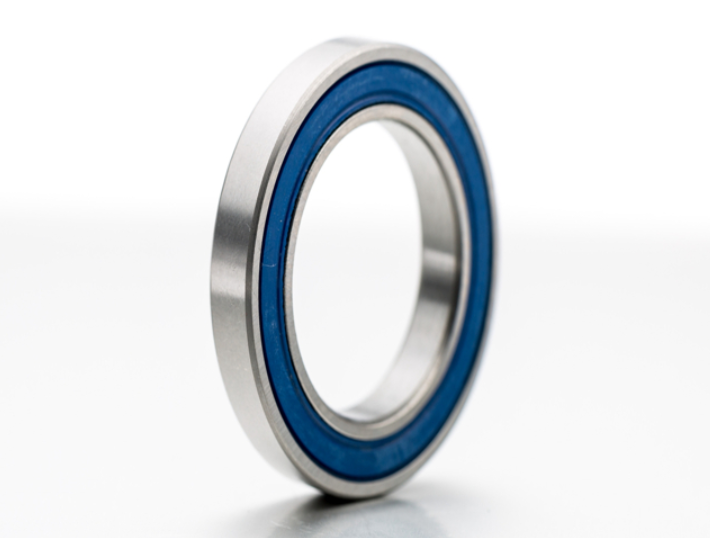

Ceramic Bearing (5)

As one of the most professional miniature bearing manufacturers and suppliers in China, we're featured by good service and competitive price. FRC miniature bearing includes Miniature Deep Groove Ball Bearings, Miniature Ball Bearings, Miniature Angular Contact Ball Bearing and so on. Please contact us for more details!

Quick Details

Type:BALL

Structure:Deep Groove

Applicable Industries:Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Home Use, Retail, Printing Shops, Construction works

Bore Size:1 - 15 mm

Model Number:All Metric & Inch Series

Precision Rating:ABEC-1 3 5 7

Seals Type:ZZ, 2RS, Open Type

Number of Row:Single row

Place of Origin:Fujian, China

Ceramic Bearing Bore:Bore(3/64"-1/2") Outer Diameter(5/32"-3/4")

Ceramic Bearing Ring's Material:

AISI52100, AISI440C, AISI304, AISI316,Ceramic(Si3N4 and ZrO2)

Ceramic Bearing Retainer Type:

CROWN retainer, Ribbon Retainer

Ceramic Bearing Retainer material:

Stainless Steel,PTFE, Nylon, PEEK

Vibration level codes:

V4, V3, V2, V1

Internal Clearance Code:

C0,C2,C3,C4,C5

Lubrication:

oil,grease,dry

Balls:

Ceramic Balls (Si3N4 and ZrO2)

ceramic bearing Speed:

50% faster than conventional bearings

ceramic balls weight:

40% less than steel balls, depending on size.

Supply Ability

1000000 Piece/Pieces per Month

Packaging & Delivery

Packaging Details:Ususally, every 10 sets bearing are packed into plastic tube or raped by rustproof paper and paced into carton box. Single package is available,that is,each set bearing is contained into plastic bag and then packed in small inner box. Industrial Packing: 100 pcs or 50 pcs in long plastic tubes.

Port:FuZhou

Lead Time:

Quantity(Pieces) 1 - 1000 >1000 Est. Time(days) 15 To be negotiated

The advantage of FreeRun Ceramic ball bearings:

1.High precision bearings,P4 ,P5 and P6.

2.Rings are made of refined Chrome steel.stainless steel 440C

3.Cage:Peek & PTFE cage .(can assure constant working under 250 centigrade)and peek cage also is the ideal cage for the high speed as it can provide the lubrication during bearing working, and it has the property of self-lubrications.However for normal applications, steel cage and Nylon cage is enough.

4. Balls: we use G3,G5 high precision Si3N4 ball for the high speed.

5. Radial clearance: Normal C0,or C3.

6.Not only for the high speed, but also Hybrid bearings has the

insulation functions. Hence for the small size of bore dia.40mm ,

also can be used for the insulation bearing purpose.

7.Full ball hybrid also can be produce as per our production picture.

All-ceramic bearings have good to excellent corrosion resistance, are non-magnetic and, apart from silicon carbide, are electrically insulating. All-ceramic bearings can be used in high to very high temperatures if supplied without a cage (full complement).

FreeRun is a specialized manufacturer of Hybrid Ceramic Bearing. Full Complement ceramicbearings,Ceramic Balls.

Hybrid Ceramic Bearing:

Ceramic bearings offer a significant performance improvement from those made from traditional steel. Our ceramic bearings are manufactured from silicon nitride (Si3N4), an exceptionally hard non-metallic material rated for speeds to 2 million dN, offering a wide selection of benefits.

Hybrid Bearings have steel rings and ceramic balls. Si3N4 Ball is the most popular for the balls as it has only 40 percent of the density of bearing steel but is much harder giving greater wear resistance. Zirconia is heavier with 75 percent of the density of steel so is less suitable for hybrid bearings..

Full Ceramic Bearing :

Full Ceramic Bearings are made entirely of ceramic material and are superior to common steel bearings in many ways. Ceramic is the perfect material for any application seeking to achieve higher RPM’s, reduce overall weight or for extremely harsh environments where high temperatures and corrosive substances are present. Applications such as cryopumps, medical devices, semiconductors, machine tools, turbine flow meters, food processing equipment, robotics and optics. Ceramic materials commonly used for bearings are Silicon Nitride (Si3N4), Zirconia Oxide (ZrO2), or Silicon Carbide (SiC.)

Ceramic Balls:

We are special in making Silicone Nitride Balls (Si3N4 Balls,Zicronia Balls (ZrO2 Balls),Sic Ceramic Balls , Aluminum Oxside Valve (AI203) ceramic balls.

Compared with steel, ceramic materials are noted for their better or particular characters, such as wear-resistance, corrosion resistance, high temperature resistance, electrical insulation (except SiC), non-magnetic, high strength, high rigidity, and low specific gravity. These properties qualify them for replacing steel to make bearings serve in conditions of higher speed, harsh environment and less lube, and decrease wear, noise, vibration and maintenance time of bearings, and eventually increase performance, reliability and life of bearings.